Zinc and galvanized process

Zinc is a blue-white metal. If it is mechanically polished or electrolyzed with an appropriate brightener, the surface will have an appearance similar to chromium.However, the luster of the polished surface will quickly disappear in the air. Such rapid discoloration and corrosion properties allow galvanized to ”sacrifice" itself to protect steel.

Zinc plating has a relatively low cost, protection and good appearance, making it a commonly used coating in industrial applications of fasteners, metal stamping parts, auto parts and manufacturing parts.,

It can even be used as an effective spraying base layer.

After alkaline cleaning or electrolytic cleaning, the oxides on the surface are removed by pickling. After washing with water, the workpiece is loaded into a barrel, hung with tools and immersed in the electroplating solution.At the same time, various brighteners can be added to the solution to increase gloss (to ensure high-quality products, careful control is required). After electroplating, the zinc surface can be passivated and given various translucent colors to extend the life of the coating.

Galvanized is usually suitable for screws and other small fasteners, switch panels, and various small parts that will be exposed to internal or mild corrosion conditions. For use in moderate or severe environments, the material must be coated with chromate conversion to obtain additional anti-corrosion protection.

Commercially, the thickness range of zinc deposition is 2.5um-12.7um, depending on the expected application and the required anticorrosive protection, most of which are 2.5um-7.6um, commonly known as “commercial zinc”.Commercial zinc has a high coefficient of friction, low strength, medium wear resistance, poor impact resistance, and is brittle at room temperature, but has a high ductility coefficient at 100~150℃.

In order to reduce the possibility of hydrogen embrittlement of hardened steel electroplating zinc, a baking process is required to remove hydrogen after electroplating, or diffuse hydrogen on the entire base substrate to reduce the risk of embrittlement.

Galvanized post-treatment closure

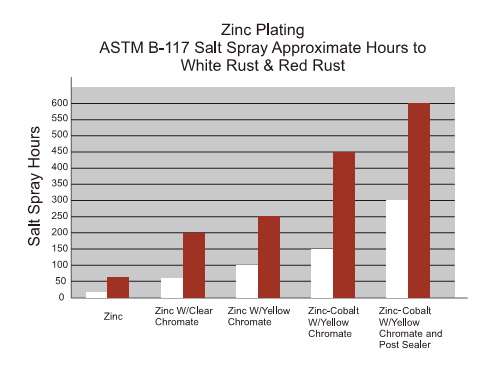

After galvanized, chromate is used for post-treatment, which greatly strengthens the anti-corrosion protection. The chemical combination of the sealant and the chromate film to seal and harden the chromate film also increases the adhesion of the zinc surface.At the same time, chromic acid leaching and fingerprint traces will be reduced, and corrosion resistance will be greatly improved.Sealants can be applied to blue, white, yellow, color, and black chromate-converted coatings.The salt spray test results showed that after the post-treatment was closed, the corrosion resistance of the workpiece increased by 50%-100%.And the red rust protection is increased to 300-500 hours.In addition, considering the importance of strengthening anticorrosive protection, the cost of closure is very economical.

Generally speaking, chromate is used on galvanized workpieces immersed in potions, containing bicromate or chromic acid and activators (usually nitric acid, sulfuric acid, chloride, formate, or fluoride).The redox reaction occurs on the metal surface in the form of metal substrate ions and trivalent chromium ions.The pH in the liquid will also increase immediately, causing a gel-like film to precipitate near the metal surface, forming a large amount of chromium hydroxide (due to soluble chromate). The newly formed coating becomes softer and more susceptible to damage after washing and drying, but it hardens quickly within 48 hours.In addition, the chromate coating itself also helps to provide some protection by forming a barrier between the metal and the environment.The protection value of chromate increases with the increase of thickness.The appearance of the final chromic acid film depends on the smoothness of the base metal and the quality of electroplating deposition.How long the protection time can be provided by the product's zinc plating depends on the thickness of the coating, corrosion conditions, post-plating treatment, and whether it is closed with chromate.

Requirements of alkaline galvanizing process and production equipment

Feeding → chemical degreasing → electrolytic degreasing → washing → pickling → washing → electrolytic degreasing → washing → acid activation → washing → alkaline neutralization → alkaline galvanized → washing → light output → washing → activation → washing → passivation → washing → sealing → drying → cutting

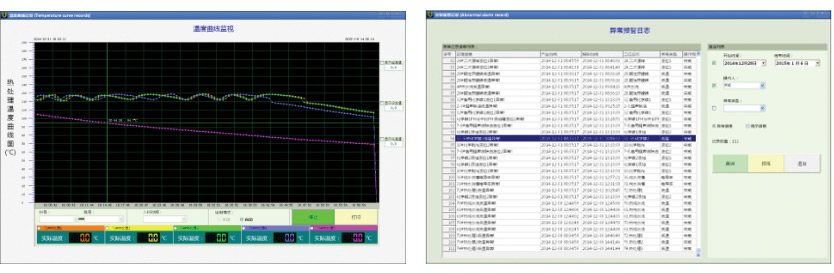

Control and data monitoring acquisition system

Electrical system: adopts a decentralized control system, using PLC, industrial computer, remote module, etc.And has a compatible and scalable system, its characteristics

-Degree of flexibility and intelligence, all process parameters and means of production are stored and recorded

-Manage the material number and batch number according to the product type

-The material number and batch number include: current, temperature, time, PH value, conductivity, fault information, peripheral auxiliary equipment, etc.

-Data reports: operation records, production records, fault records, etc.

-Electrical component brands: Schneider ® , Mitsubishi ® , Siemens ®

-Integrated system software brand: Unikeysoft ®

The world-renowned Unikeysoft ® intelligent electroplating monitoring and management system, all production parameters can be edited and adjusted by the user (administrative rights required).The system has the functions of re-line assistance and diagnosis. Users can send a remote link to our company's remote maintenance center through this system, and full-time engineers will deal with user problems in real time.

Generate charts and detailed reports for all production data